In the contemporary industrial landscape, baghouse systems have become a cornerstone for managing environmental and health concerns associated with industrial dust. As an integral part of industrial dust extraction systems, baghouse technologies offer a multitude of advantages, enhancing both efficiency and compliance in various industries. This article explores the myriad benefits that baghouse systems bring to modern industrial operations.

Enhanced Air Quality and Health Safety

Baghouse systems, as a critical component of industrial dust extraction systems, play a pivotal role in enhancing air quality within industrial facilities. By efficiently capturing airborne particulates, these systems significantly reduce the amount of dust and debris in the air. This not only creates a healthier environment for employees, reducing the risk of respiratory problems and other health issues, but also contributes to a cleaner, more sustainable working environment.

Compliance with Environmental Regulations

In today’s regulatory landscape, compliance with environmental standards is more crucial than ever. Implementing a baghouse system ensures that industries meet stringent air quality regulations. This is especially important as governments and environmental agencies impose tighter controls on industrial emissions. A reliable baghouse manufacturer can provide systems that are designed to meet specific regulatory requirements, thus aiding industries in maintaining compliance.

Operational Efficiency and Cost-Effectiveness

Baghouse systems contribute significantly to the operational efficiency of industrial dust extraction systems. By maintaining cleaner air, they reduce the need for frequent equipment maintenance and cleaning, thereby minimizing downtime. Moreover, the longevity and low maintenance requirements of these systems make them a cost-effective solution for dust control in the long term, offering substantial savings over other dust collection methods.

Versatility Across Various Industries

The versatility of baghouse systems is a key advantage, as they can be adapted to a wide range of industrial applications. Whether it’s in the cement, mining, pharmaceutical, or woodworking industries, these systems can be customized to handle different types of dust and varying volumes. This adaptability makes them an ideal choice for many sectors, providing effective dust control solutions tailored to specific industrial needs.

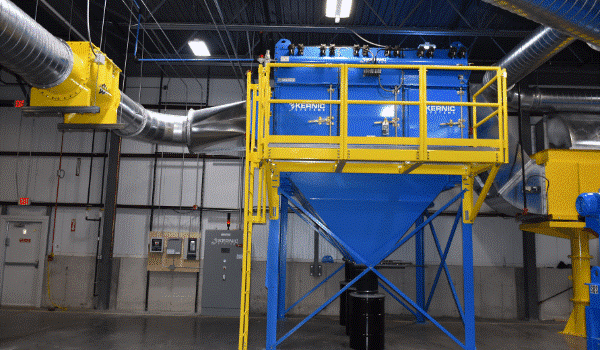

Technological Advancements and Innovation

The field of industrial dust extraction is continuously evolving, and baghouse manufacturers are at the forefront of this innovation. Modern baghouse systems are equipped with advanced features like automated controls, energy-efficient designs, and improved filtration materials. These technological advancements enhance the overall effectiveness and efficiency of dust collection, keeping industries at the cutting edge of environmental management practices.

Long-Term Environmental Sustainability

Implementing a baghouse system is a step towards long-term environmental sustainability. By efficiently managing industrial dust, these systems help in reducing the overall environmental footprint of industrial operations. This is increasingly important as businesses and consumers alike are becoming more environmentally conscious. Industries that adopt sustainable practices, such as effective dust control, are better positioned in the market and can often benefit from incentives aimed at promoting environmental responsibility.

In conclusion, the implementation of baghouse systems in modern industries offers a host of advantages, ranging from enhanced air quality and regulatory compliance to operational efficiency and long-term sustainability. As industries continue to evolve and face new environmental challenges, the role of industrial dust extraction systems, particularly those designed by skilled baghouse manufacturers, becomes ever more crucial in ensuring a safe, efficient, and environmentally responsible industrial landscape.

For More Information visit Our Homepage: