Introduction:

The term “automotive industry” refers to the businesses and processes that go into making cars and trucks, including the majority of parts like engines and bodywork, but not gasoline, tyres, or batteries. Passenger cars and light trucks, such as SUVs, vans, and pickups, make up the bulk of the industry’s output. Delivery trucks and big transport trucks, sometimes known as semis, are commercial vehicles, however they play a supporting role in the business. The articles automobile, truck, bus, and motorbike cover the design of contemporary automotive vehicles, while petrol engine and diesel engine explain automotive engines. Transportation, History of: The Ascent of the Automobile details the evolution of the vehicle.

The impact that the automotive industry had on the twentieth century makes its relatively short history all the more intriguing. Even though the car wasn’t invented in America but rather in Europe in the latter part of the nineteenth century, the United States had total control over the industry for the first half of the twentieth century because to its innovation of mass manufacturing techniques. The scenario changed dramatically in the second part of the century when western European nations and Japan became as important exporters and producers.

Background:

The invention of the petrol engine in the 1860s and ’70s, primarily in Germany and France, laid the groundwork for the automobile industry, even if steam-powered road vehicles had been manufactured earlier. Manufacturers from the United Kingdom, Italy, and the United States joined their French and German counterparts around the turn of the twentieth century.

Events leading up to the First World War

There were hundreds of little firms that created a few hand-built automobiles in the early days of the automotive industry, and almost all of them went out of business very quickly. There were commonalities among the few number that made it into the age of mass manufacture.

To begin, there were three clearly defined groups: those who made bicycles (like the Germans and the British at Morris), those who made horse-drawn vehicles (like the Americans at Durant and Studebaker), and, most often, those who made equipment. Daimler, Lanchester, and Olds were the manufacturers of stationary gas engines; Vauxhall, of marine engines; Land, of machine tools; Woolseley, of sheep-shearing machinery; Peerless, of washing machines; White, of sewing machines; and Panhard and Levassor, of France, of woodworking and milling machinery.

Buick manufactured plumbing fittings, such as the first enamelled cast-iron bathtub, whereas Pierce manufactured birdcages. The United States’ Ford and the United Kingdom’s Rolls-Royce were two prominent outliers to this trend; they were both established as automobile manufacturers by partners with complementary commercial and engineering backgrounds.

Almost every manufacturer in the US was an assembler, meaning they took parts made by other companies and put them together. The assembly process was also well-suited to a beneficial finance strategy. The concept of buying components on credit and selling completed automobiles for cash allowed for the production of motor vehicles to begin with a small commitment of capital; since then, the sale of motor vehicles in the United States has revolved around the cash transaction between manufacturer and dealer. During this time, European automakers were more likely to produce all of their own parts.

The pioneering automaker had to make a fundamental decision about what to create in addition to resolving the technical and financial issues of entering production. Many people started experimenting with steam and electricity when the petrol engine became successful. The electric car really had the most popularity for a while due to its simplicity and lack of noise, but the constraints of battery capacity eventually killed it in the marketplace. Electric automobiles were still in restricted manufacture even into the 1920s, despite their immense popularity among women. Even as late as 1929, one of the most persistent manufacturers, Detroit Electric Car Company, continued regular operations.

The widespread use of the so-called flash boiler, which allowed for the quick raising of steam, after 1900, benefited steam power, a more formidable competitor. Since it did not need a complex gearbox, the steam automobile was simple to run. However, in order to make the engine lightweight enough for use in a road vehicle, high steam pressures were necessary; building and maintaining engines that met these criteria was costly and arduous. Petrol engines had mostly replaced steam engines by 1910. On the other hand, American brothers Stanley kept making steam cars all the way until the 1920s.

There were patent disputes in the early years of the automobile business, as there are with any new invention. Notable among these were two protracted legal battles in the US and UK, when promoters filed extensive patents in an effort to corner the market on the emerging sector. After five years of waiting for a patent, the claim was finally denied by British courts in 1901. Ford was embroiled in a legal dispute with the Association of Licenced Automobile Manufacturers in the US on the Selden patent.

The latter group asserted that the patent covered the essentials of gasoline-powered cars. The patent was deemed “valid but not infringed” by Ford in 1911, according to the courts. The primary outcome of the ruling was the establishment of the Alliance of Automobile Manufacturers’ forerunner in 1915 to oversee a patent cross-licensing arrangement.

Big production

The advent of full-scale mass production—a process that combines accuracy, standardization, interchangeability, synchronisation, and continuity—was the automobile industry’s most notable contribution to technical improvement. America was the first to implement mass manufacturing. After some preliminary investigation in the nineteenth century, the method found its natural home in the United States due to its vast population, high level of living, and great distances.

The popular portrayal of standardisation and interchangeability as “the American system of manufacture” placed American efforts front and center, even though Europe had participated in the experiments as well. The basic techniques were known, but they had never been used to produce a mechanism as complicated as a motor vehicle before (refer to work, history of the organisation of).

In 1908, at the British Royal Automobile Club in London, the “American system” of parts interchangeability was dramatically shown: three Cadillacs were taken apart, mixed, and 89 parts were taken out at random and replaced from the dealer’s stock; the cars were then put back together and driven 800 km (500 miles) without any problems.Cadillac Motor Car Company founder Henry M. Leland, who was also responsible for this display of showmanship, later collaborated with renowned electrical engineer Charles F. Kettering to create the electric starter, a game-changing invention that helped popularise gasoline-powered cars.

During WWII, the automobile industry

The manufacturing prowess of the automobile industry initially proved its worth to the war effort during World War I. Transport and supply were both facilitated by the widespread use of motor vehicles. Furthermore, factories that produce automobiles might easily be adapted to produce tanks and aeroplanes. The American industry, which was only active for a brief period, never made full use of its capability, and the conversion of automotive plants was an afterthought for all the combatants, an unplanned measure done after hostilities began.

When WWII loomed on the horizon, the automobile companies ramped up their preparations to pool their resources. Using administrative and technical staff from the automobile sector, the British government established “shadow factories” next to its automotive facilities. These factories were prepared to transition into military manufacture, namely aircraft, in the event of war. Late and ineffectively, France tried to convert. Full conversion of the German automobile industry to military manufacture did not occur until 1943.

This industry produced the military vehicles required for blitzkrieg. Prior to 1940, the United States made almost no attempt to prepare for industrial mobilisation. In fact, restrictions on civilian vehicle manufacture were not even considered until after the December 1941 attack on Pearl Harbour. However, once its resources were directed into war manufacturing, the American automobile industry made a remarkable contribution due to the concentration of its productive capacity and expertise.

The automobile industry produced about $29 billion worth of war goods from 1940 to 1945, accounting for one-fifth of the nation’s total production. The number of vehicles produced went much beyond only trucks and Jeeps; the list includes 2,600,000 military trucks and 660,000 of them. A large portion of the U.S. military hardware, including machine guns, carbines, tanks, armoured cars, and helmets and aerial bombs, came from automotive companies.

It turned out to be more difficult than expected to adapt automotive plants for aircraft manufacture. It was not easy to modify an automotive engine factory to make them suitable for airframes, and neither were automobile assembly factories. Automobile manufacturers made substantial contributions to aeroplane manufacturing after these issues were overcome.

With the world’s second-largest automotive sector at its disposal, Britain was better able to put its resources to use. Austin, Morris, Standard, Daimler, Ford, and Rootes were among the companies that helped meet the wartime demand for aircraft and aviation engines by their participation in the shadow factories. Tanks were manufactured by Vauxhall and Leyland Motors.By utilising Morris Motors’ sales and service organisation, Lord Nuffield established a system for repairing aircraft, which was later expanded to other minor contractors, making a substantial contribution to the manufacturing effort.

While the United States and Britain had relatively large automobile industries, the other belligerents had far larger facilities for the manufacturing of weaponry. As a result, satisfying the ravenous demand for automobiles became the primary focus of the automotive manufacturers in these nations. This is how the numerous Ford properties that were seized by the Germans were put to use, as well as Volkswagen, which produced the jeep in Germany. Having been in the tank manufacturing business since WWI, Renault first supplied tanks to Germany and then France.

After 1945, the car industry

The manufacture of motor vehicles had a remarkable surge following World War II. The global production expanded by a factor of nearly ten during the course of 35 years. One notable aspect of this growth is that the majority of it happened in countries other than the US. The United States’ proportion of global automobile production decreased from around 80% to 20% even while output was going up.

The US was the world’s top producer right up until the recession hit in the ’80s. Japan, which had minimal car production before to the war, surpassed the European Economic Community (EEC) as the top producer in 1980. In 1994, the United States took back the lead in car manufacturing again. This was because, in response to political and economic constraints in their key foreign markets, Japanese automakers were increasing output at plants in the United States and other countries. Having said that, China surpassed all other automakers in terms of production in the early 2000s.

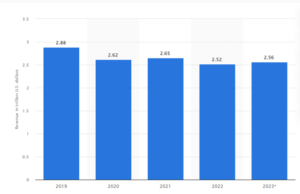

Revenue from the production of motor vehicles around the globe from 2019 to 2022, with an outlook for 2023

(in trillions of dollars)

Gross revenue – global automotive manufacturing sector 2019–2023.

Forecasts indicate that the global automobile manufacturing market would expand from its 2021 valuation of around 2.86 trillion USD to a further 2.95 trillion USD in 2022, reflecting a gradual upturn but still falling short of the industry’s 2019 market size.

Markets are being shaken by automation and electrification

The next ten years will see massive advancements in automotive technology. By 2030, electric vehicles will account for around 26% of all new car sales, and the world’s fleet will include about 58 million self-driving cars.

Potentially new opportunities for suppliers

Electronic components, especially automotive semiconductors, will become even more important for automotive manufacturing as autonomous and electric vehicles dominate the market. Technological advancements are already impacting the types of parts needed to complete the finished product, which is leading to further segmentation in the auto supplier industry, especially within the automotive electronics industry.

Global automobile production forecasted from 2000–2022,

expressed in million vehicles

Global manufacturing of motor vehicles from 2000 to 2022

With 85 million motor vehicles manufactured globally in 2022, an increase of almost six percent from the previous year, the top three countries producing automobiles and commercial vehicles were China, Japan, and Germany.

The manufacturing is led by China.

China has become one of the most important growth markets for global automakers in recent decades, and the country is now the largest producer of passenger cars in the world, with over 21 million cars produced in 2021 and nearly a third of the world’s total.

U.S. factories in China

Shanghai General Motors Company Ltd, also known as Shanghai GM, is one of China’s leading automakers and a joint venture between General Motors and SAIC Motor Corporation Limited. GM makes and sells passenger vehicles under the Chevrolet and Cadillac brands, among others. In addition to cars, the company also makes engines and gearbox systems. In 2021, Shanghai GM produced just over 1.3 million units.

Gross sales of motor vehicles worldwide from 2005 to 2022

Global sales of motor vehicles in automotive industry from 2005 to 2022

The global motor vehicle sales market had a 1.4% year-over-year decline in 2022. The industry began to recover after two years of declining demand in 2021, but a scarcity of semiconductors caused a

Prospects for 2020

In 2020, sales of motor vehicles plummeted. Across the board, sales dropped in the first half of the year due to countries implementing COVID-19 lockdown measures. Despite rising demand for plug-in electric vehicles and sales in China, the biggest automotive market in the world, these factors were not enough to compensate for the overall slump. As economies gradually recovered, production facilities sat idle for a while due to supply chain bottlenecks.

Demand in China is evolving

Sales of new passenger vehicles have been boosted by China’s burgeoning middle class as a result of the country’s rapid economic expansion. However, this growth in sales cannot be sustained indefinitely. Chinese consumers have recently shown a shift in their preference for motors, with electric vehicles, luxury cars, and SUVs seeing the most growth. In contrast, internal combustion engines are perceived as being outdated. China is currently the world’s largest market for electric vehicles and is expected to maintain this position for the next decade.

Automotive Industry Books on a Global Scale

Book 1

Automotive Global Value Chain by Wilson Kia Onn Wong

Call Number: HD9710.3.A2 W66 2018

ISBN: 9781138237049

Published/Created: 2017-09-01

Today, some suppliers have grown increasingly powerful and in certain cases, earn revenues that rival or even exceed that of their automaker clients. —From publisher’s description.

Book 2

Crisis, Resilience and Survival by Matthias Holweg; Nick Oliver

Call Number: HD9710.A2 H647 2016

ISBN: 9781107076013

Published/Created: 2015-12-01

This book traces the history of the automobile industry across the world and shows how it has changed over the years, shedding light on the difficulties and pressures that companies face in this massive and unpredictable market.

Book 3

Geely drives out : the rise of the new Chinese automaker in the global landscape by Hua Wang, Giovanni Balcet, Wenxian Zhang

Call Number: HD9710.C64 Z457 2021

ISBN: 9789811234422

Published/Created: 2017

This book delves into the rise of Geely, a privately-owned automaker in China, and how it has fared since 2008, a time when global automotive manufacturing has been faltering. The transformation of the Chinese auto industry into the world’s largest producer is a reflection of China’s robust manufacturing economy.

Book 4

Global Automobile Demand by Bruno Jetin (Editor)

Call Number: HD9710.A2 G55 2015

ISBN: 9781137516138

Published/Created: 2015-07-08

The first volume of Global Automobile Demand takes a look at car demand in mature economies like the US, UK, France, Germany, Spain, Japan, and Korea. The second volume delves into the effects of the Great Recession and the structural factors that influence demand in developing and developed nations.

Book 5

Globalization of Indian Industries by Filip De Beule (Editor); K. Narayanan (Editor)

Call Number: HD9710.A2 H647 2016

ISBN: 9789811000836

Published/Created: 2015-11-07

The effects of FDI on the Indian economy are examined in this book, which primarily concerns the industrial sector. The effects of FDI on exports and FDI by Indian enterprises are also discussed.

Book 6

Who Really Made Your Car? by Thomas H. Klier; James M. Rubenstein

Call Number: HD9710.3.U52 K55 2008

ISBN: 9780880993333

Published/Created: 2008-07-01

According to the publisher, this book provides an in-depth analysis of a sector that is becoming increasingly important in the American auto industry.